The Reality of Classic Defender Ownership: Problems You Need to Know

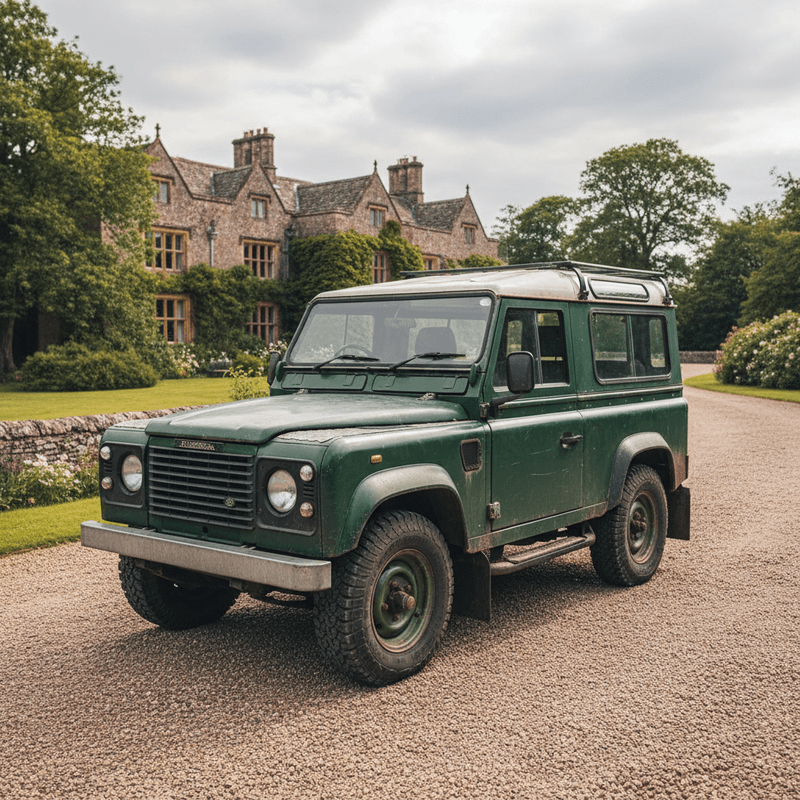

Land Rover Defenders inspire fierce loyalty among their owners, and for good reason. These iconic vehicles offer unmatched capability, timeless design, and a driving experience that connects you directly to the terrain beneath your wheels.

But let's be honest about what classic Defender ownership really means. These vehicles were built for utility over luxury, and their reliability reflects priorities from a different era. While modern Defenders have dramatically improved (scoring 96.3% reliability in recent What Car surveys), classic models present a unique set of challenges that every owner should understand.

The problems fall into predictable categories: chassis corrosion, engine-specific issues, electrical gremlins, and drivetrain wear. Understanding these patterns helps you make informed decisions about purchase, maintenance, and restoration.

Most importantly, these aren't random failures. They're systematic issues that stem from the original engineering constraints and the natural aging process. The good news? Every problem has a solution, and many can be prevented with proper maintenance or eliminated entirely through comprehensive restoration.

Chassis and Corrosion: The Defender's Achilles' Heel

Every classic Defender owner eventually faces the same reality: chassis rust is inevitable. The rear crossmember fails first, usually between 15-20 years regardless of maintenance quality. This isn't a design flaw—it's physics.

The rear crossmember bears enormous stress from the suspension mounting points while being exposed to road salt and moisture. Made from mild steel rather than the aluminum body panels, it simply cannot match the longevity of the rest of the vehicle.

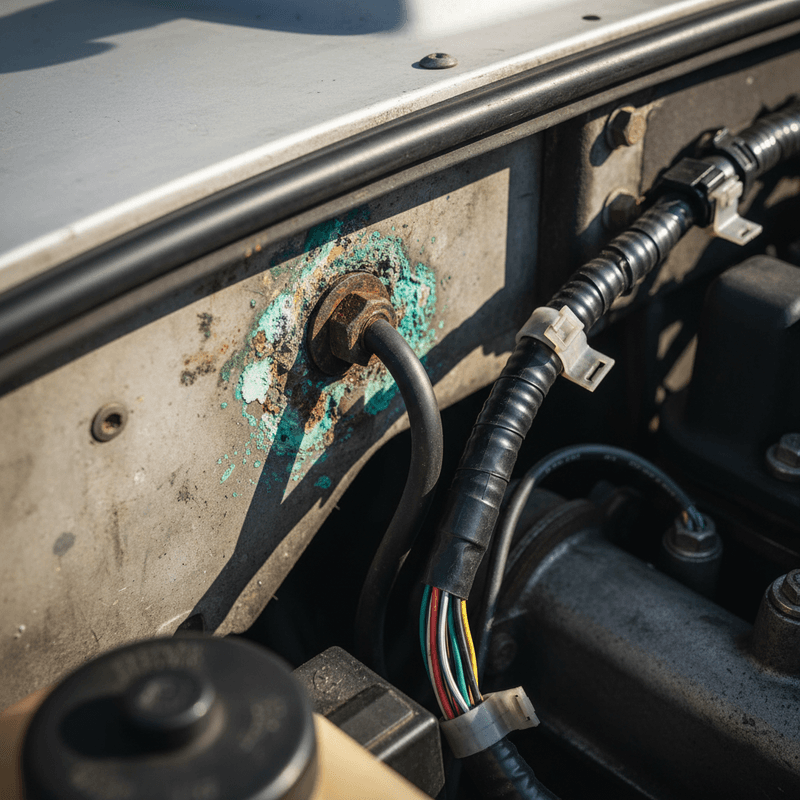

Bulkhead corrosion presents an even more serious concern. When the structural integrity of the cabin framework deteriorates, repair costs escalate quickly. The bulkhead houses critical electrical connections and supports the dashboard, steering column, and pedal assemblies.

Expert Tip: Galvanic corrosion between steel and aluminum components accelerates deterioration. The different metals create an electrochemical reaction that promotes rust formation, particularly around mounting points and joints.

The prevention versus repair equation is stark. Annual rust treatment might cost £200-500, while rear crossmember replacement typically runs £2,000-4,000. Complete chassis restoration starts at £15,000 and can exceed £30,000 for comprehensive work.

This reality has made galvanized chassis upgrades increasingly popular. A properly galvanized chassis eliminates corrosion concerns for decades, representing one of the most valuable investments in any Defender restoration project.

Engine Woes: From Simple TDI to Complex TD5

The engine landscape varies dramatically across Defender generations. 200TDI and 300TDI engines represent the sweet spot of reliability—simple, robust, and easily maintained. These engines regularly exceed 300,000 miles with basic maintenance.

Common TDI wear points include turbo seals, injection pump components, and timing belt tensioners. None represent catastrophic failures, and replacement parts remain readily available and reasonably priced.

TD5 engines introduced sophisticated electronics that transformed performance but complicated reliability. The injection system delivers excellent power and efficiency, but three critical vulnerabilities plague these engines:

- Injector harness oil migration causes starting problems and rough running

- Head gasket failures typically occur between 80,000-120,000 miles

- Oil pump drive failures can destroy engines if not caught early

Expert Tip: TD5 engines require specific maintenance intervals and high-quality oil to maintain reliability. The sophisticated injection system is intolerant of contamination or service neglect.

Puma TDCi engines brought Euro 4 emissions compliance but introduced new complexities. ECU problems, injector faults, and output shaft spline wear create expensive repair scenarios. The MT82 gearbox output shaft particularly suffers from premature wear.

Modern Defender engines have largely solved these historical issues, but at the cost of increased complexity and diagnostic requirements that challenge traditional independent servicing.

Electrical Gremlins: Ground Faults and Wiring Nightmares

Defender electrical problems often baffle owners because symptoms seem random and intermittent. The root cause is usually mundane: poor grounding connections and corroded wiring harnesses.

The bulkhead earthing point becomes corroded over time, creating resistance that manifests as flickering lights, false warning signals, and system malfunctions. This single connection point affects nearly every electrical system in the vehicle.

Common electrical symptoms include:

- Headlights dimming with engine RPM changes

- Warning light clusters illuminating randomly

- Central locking operating inconsistently

- Gauge cluster displaying incorrect readings

Wiring harness deterioration creates cascading problems. As insulation breaks down and connections corrode, electrical resistance increases throughout the system. Individual component failures often result from voltage drops rather than component defects.

Expert Tip: Many "component failures" in classic Defenders trace back to electrical supply problems. Always verify clean power and ground connections before replacing expensive components like ECUs or instrument clusters.

Modern Defenders face different electrical challenges. Software glitches, infotainment system freezes, and complex diagnostic requirements reflect the transition to sophisticated electronic architecture.

Drivetrain Troubles: Gearbox and Transfer Box Issues

The R380 gearbox serves most classic Defenders reliably, but layshaft bearing wear and 5th gear mechanism problems affect high-mileage examples. Bearing noise typically develops gradually, while 5th gear issues manifest as difficulty engaging or staying in gear.

Transfer box reliability depends heavily on maintenance history. Oil seal failures are common and progressive—small leaks become major failures if ignored. Internal component wear affects low-range engagement and can create expensive repair scenarios.

The MT82 gearbox in Puma models introduced output shaft spline wear problems. This specific failure can render vehicles undriveable and requires specialized parts that aren't always readily available.

Clutch and flywheel problems affect all manual Defenders. Heavy use, particularly with larger tires or increased power output, accelerates wear. Dual-mass flywheels in later models add complexity and expense to clutch replacement.

These drivetrain issues rarely leave you stranded immediately, but they create progressive deterioration that eventually requires comprehensive attention.

The Monarch Solution: Why Frame-Off Restoration is the Answer

Understanding Defender problems reveals why piecemeal repairs often disappoint owners. Frame-off restoration addresses all systemic issues simultaneously, creating a vehicle that exceeds original factory standards.

The process begins with complete disassembly, allowing comprehensive inspection of every component. Galvanized chassis replacement eliminates corrosion permanently. Complete rewiring with modern harnesses and improved grounding eliminates electrical gremlins.

Engine rebuilding or replacement ensures reliability for decades. Drivetrain refurbishment addresses wear patterns before they become failures. The result is essentially a new vehicle with classic character and modern dependability.

From an investment perspective, frame-off restoration makes financial sense. The alternative—addressing problems as they arise—typically costs more over time while never achieving comprehensive reliability. A properly restored Defender requires only routine maintenance for years.

Quality restoration work transforms problematic classics into dependable daily drivers. The galvanized chassis alone justifies much of the investment, while systematic component replacement creates reliability that exceeds new vehicle standards.

Modern restoration techniques address original design limitations. Improved wiring layouts, enhanced cooling systems, and upgraded suspension components create better-than-new performance and durability.

Ready to Transform Your Defender?

Classic Defender ownership doesn't have to mean constant repairs and reliability concerns. Frame-off restoration eliminates these problems permanently while preserving the character and capability that makes these vehicles special.

At Monarch Defender, we understand every problem discussed in this guide because we've solved them countless times. Our comprehensive restoration process addresses chassis corrosion, electrical issues, engine problems, and drivetrain wear systematically.

The result is a Defender that combines authentic character with modern reliability—a vehicle you can depend on for daily driving or adventure touring without the constant worry of breakdown.

Want a defender without Defender problems? Contact our restoration specialists to discuss how frame-off restoration can transform your vehicle into the reliable adventure partner you've always wanted.